HIGH PERFORMANCE STEEL FOR INFRASTRUCTURE

Many of us who visited Bangkok may have enjoyed a river cruise and noticed the number of Bridges. I counted 16 or 17 on my visit, a few years ago, and then gave up. In fact, there are over 40 Bridges over the Bangkok River, and more are being built. The Thai capital has grown on both sides of the river with the river as the main lifeline communication for industrial raw materials and the bridges providing the mobility in land-based transportation. Of course, multi-level elevated expressways crisscross the most densely built part of the city.

To cite another example, the Beijing- Shanghai 1300 kilometer high-speed rail line that connects two of China's largest economic hubs with the seaport has 244 bridges and 22 tunnels along the way, and 87% of the railway is elevated. Some 220 trains use the tracks every day, and the journey takes less than 4 hours.

By contrast, there is a single bridge over the Karnaphuli in Chittagong and two bridges across the Buriganga and three across the Sitalakhya in Dhaka. The train journey from the capital city to the port city takes 8 hours. It is not surprising; poor infrastructure has contributed to immense urban congestion and poor quality of life for our people. It has impeded urban growth and industrial investment.

According to Dr. Biru Paksha Paul, the Chief Economist of the Bangladesh Bank the two major cities and its corridor, the Dhaka-Chittagong highway alone represents 50% of the GDP of the entire country. With a modern infrastructure, the two cities will work as the engine of growth for the national economy. To attain global standards of competitiveness, we need 100 bridges across the rivers in Dhaka and Chittagong. Speed and mobility are the essences of a modern economy, and a viable infrastructure is a key to it.

A modern infrastructure is built on tens of millions of tons of steel. Steel is a ubiquitous material; it is present inside a structure and hidden from view. It is present in the floors under our feet and on the roofs over our heads, either in an office building or an apartment building or a shopping mall. It is present in the cars we drive and in the bridges that we cross the river.

All infrastructures are highly steel intensive. For example, the 10 kilometer long, Mayor Hanif Flyover in Dhaka used 2500 tons of reinforcing steel for every kilometer. Along with transportation, the country needs an energy infrastructure as well. This is steel intensive as well. A 1500 MW nuclear power plant requires over 50,000 tons of steel in its construction. This is over 33 tons per MW of installed capacity. A coal-fired power plant, of the same rating, requires even more, around 98 tons per MW of installed capacity. Natural Gas fired combined cycle power plants need 3.3 tons per MW and 460 tons per MW for wind power plants! [Figures are from a University of California, Berkeley study]

Countries with the highest standard of living have the highest per capita investment in capital assets built with steel. This is known as the Steel Intensity Index or SII. The total quantity of steel asset of a country [built into its bridges, power plants, residential and commercial buildings and transportation vehicles and factory machinery] divided by the GDP gives the SII of a nation. Australia and Canada, two of the wealthiest nations in the world have SII values over 12 kg. per capita. Japan has the world's highest SII of 13.6 while Bangladesh trails at 0.1. This is not surprising, as a nation we have just embarked on a serious power and transportation infrastructure building journey. [The figures are from an econometric study at the Lulea University of Technology, Sweden]

Steel is an expensive material, and it will be needed in tens of millions of tons to attain our national Vision 2030. The current design standard followed by the various Govt. Agencies for the design of Buildings, Bridges, and Power plants is based on the use of Grade 60 reinforcing steel. Replacing the Grade 60 reinforcing steel with the new generation Grade 80 steel means 20% less steel is consumed in construction. The price of Grade 60 and Grade 80 is practically same. The savings based on a hypothetical ten million tons of steel consumption per annum in power and transportation infrastructure projects is around TK. 100 Billion at current steel prices. Our Building and Bridge Construction codes have to be upgraded in light of recent advances in high strength steel usage in countries such as Japan, which has started using Grade 100 steel.

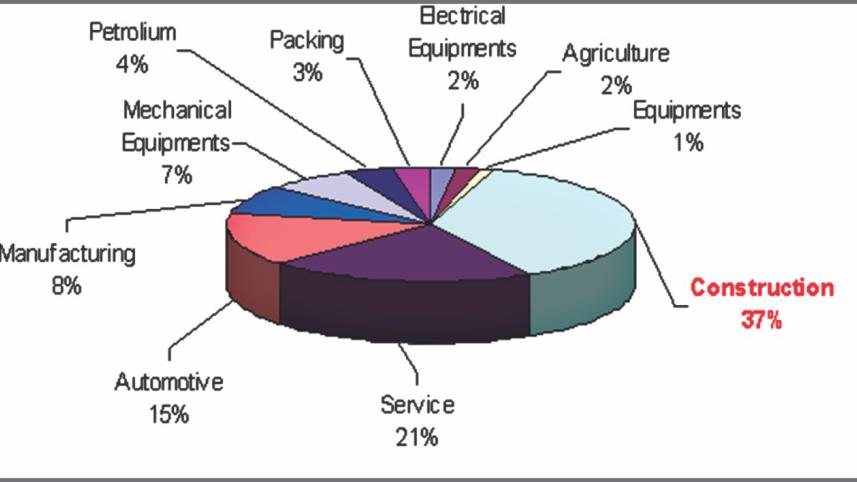

The quest for superior performance high strength steel becomes more meaningful if the total global steel consumption pattern is analyzed. The pie chart, below shows 37% of the steel used world-wide is in construction activities. [Source: World Steel Dynamics]

Global preference for rebar of higher strength and better ductility characteristics is universal, across Asia, Europe and the Americas. All the main construction codes, throughout the world, emphasize the use of steel with extra-high-yield strength and extra ductility. This is known as High-Performance Steel.

The first High-Performance Steel, in Bangladesh, was successfully manufactured by BSRM in early 2015. Since then it has been tested in BSRM's testing facility and Bangladesh University of Engineering & Technology (BUET) It fully conforms to the U.S. standard ASTM A-706 Grade 80 of 2014 and the ISO 6935-2 Grade 600 of 2015.

It may be mentioned, the 28 member European nations common Concrete standard Eurocode 2 has permitted the full use of Grade 600 steel in since 2005, and our neighbor India Standard I.S. 1786 endorsed Grade 600 in 2008. The U.S. ASSHTO code for Bridges recommended Grade 75 steel in 2012.

The writer is Head, Product Development, BSRM Group.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments